There is no glamour in the control valve like there is in distributed control systems. Would any new engineer that graduated from distinguished University be interested in pipe, gasket, flanges, and packing and bothered working with dirt, mud, oilywater when “interfaced” with hardened stainless steel valve trim. It is also hard to hide a 400lb valve under your coat if you make mistake in sizing and selection and the valve needs to be changes.

Fig 1 Debris was found inside the control valve between the plug and seat ring

Fig 2. valve cage

But there are some reason for using valves. they work and they are great to stand on for you to reach field mounted transmitter reached. If you are still interested, the following subject may be important for choosing the right control valve.

Control Valves Type and Body Design

Control valves can be classified based on body design as follow:

Control valve selction table can be seen in control-valve-operation-and-design-criteria-for-beginners-2/

Valve Body Assembly:

Valve Trim:

In the globe valve , the trim would be typically include valve plug, seat ring, cage, stem and stem pin. Valves control the rates by introducing a pressure drop across the valve trim.

Bonnet Assembly:

Bonnet Assembly: An assembly including the part through which a valve plug-stem moves

and a means for sealing against leakage along the stem. It usually provides a means for

mounting the actuator.

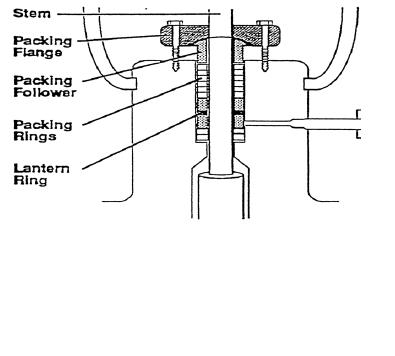

Packing Assembly:

The part of the bonnet assembly used to seal against leakage around the valve plug stem.

Included in the complete packing box assembly are various combinations of some or all of

the following component parts: Packing, Packing Follower, Packing Nut, Lantern Ring,

Packing Spring, Packing Flange, Packing Flange Studs or Bolts, Packing Flange Nuts,

Packing Ring, Packing Wiper Ring, Felt Wiper Ring. Figure below shows Packing box

assembly.

Fig3. Bolted Packing Box Assembly

Fig 4. V Shape Teflon Packing

Trim Design And Component of Globe Valve

The shape of plugs, seats and cages to obtain the desired Flow characteristic would be a function of trim design, The term trim applies to the parts of a part that come into contact with the flowing fluid (wetted part)

Plug

Plug shapes determine valve flow characteristics.

Seats

The seat or seat ring is that portion of the valve trim ot body that plug contacts for closure, the seat ring may be screwed or welded to the body, Metal to metal contact is standard practice. but when tight shut-off is required, soft seat made of teflon, hard rubber or other resilient composition of material are used to provide the necessary tight closure

Cages

Cage is a hollow cylindrical trim element that is a guide to align the movement of a valve plug with a seat ring in the valve body. The walls of the cage usually determine the flow characteristic of the control valve as shown in Fig below

Rule of thumb for each characteristic

- Linear trim are used in situations, where the pressure drop across the valve is constant (eg level control)

- Equal Percentage trims are best used in flow situation where the pressure drop across the valve will vary as the flow goes from its minimum value to its maximum value, (eg pressure & flow control)

- Quick opening valves are useful in by pass or re-cycle lines where a basic on-off control of flow is required

Valve Manufacturer.

But hey, why bother? There is always a good vendor around to help you up choosing the best valve that will suited to your process.

All you have to do is just give them the process data and you will get the calculation, type of the valves and ask for vendor warranty if something goes wrong.

It would be nice if this happened in the real life, A warranty usually is only as good as the quality of the equipment it self. Vendors have their own problem too. The author’s acquaintance who work in valve manufacturer said that the company salary rate is usually too small to employ an experienced instrument engineer and no one understands the severity of the plant environment or the difficulty of the process application. By the end the user suffers from the same lack of knowledge as the manufacturer .

Thanks for taking the time to discuss that, I feel strongly about this and so really like getting to know more on this kind of field. Do you mind updating your blog post with additional insight? It should be really useful for all of us.

ReplyDeleteball valve manufacturers in usa

Thanks for taking the time to discuss this, I feel strongly that love and read more on this topic. If possible, such as gain knowledge, would you mind updating your blog with additional information? It is very useful for me.

ReplyDeleteRobinets de Lavabo

Great tips, many thanks for sharing. I have printed and will stick on the wall! I like this blog. Basket Strainer

ReplyDelete